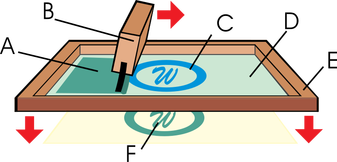

Silk Screen / Screen Printing

When screen printing apparel, an underbase of white is needed on a colored product (no underbase needed if the product is white) in order for art to be imprinted on top of that white layer. This ensures color-matching. We could always print without the underbase to create a vintage look and feel, but keep in mind that the colors being imprinted will be laying on a colored surface, so that colored surface will manipulate the colors being imprinted directly on it.